It is presently used mostly in interiors as decoration, but is making its foray into exterior structural walls.įigure 2: Translucent concrete has been used in art installations in museum exhibits. In its early days, it was used mostly in art installations (see Figure 2) and material demonstrations such as the Liquid Stone exhibit at the National Building Museum, and a sidewalk in Stockholm that looked “like an ordinary sidewalk by day but illuminated at night by lights under it”. So far translucent concrete has been used to make light installations, signs, and fixed-in-place furniture such as benches, desks, and counters. According to one German company, it can be used “for ventilated facade systems as well as for interior cladding”. This allows translucent concrete to be used for a variety of purposes, from a thin veneer to a structural system. The blocks come in a range of sizes, the maximum for glass fiber being 1200 x 400 mm (47.2 x 15.7 inches), and the thickness can range from 25-500mm (1-20 inches). It can only be produced as pre-cast or prefabricated blocks and panels it cannot be poured on site like traditional concrete.

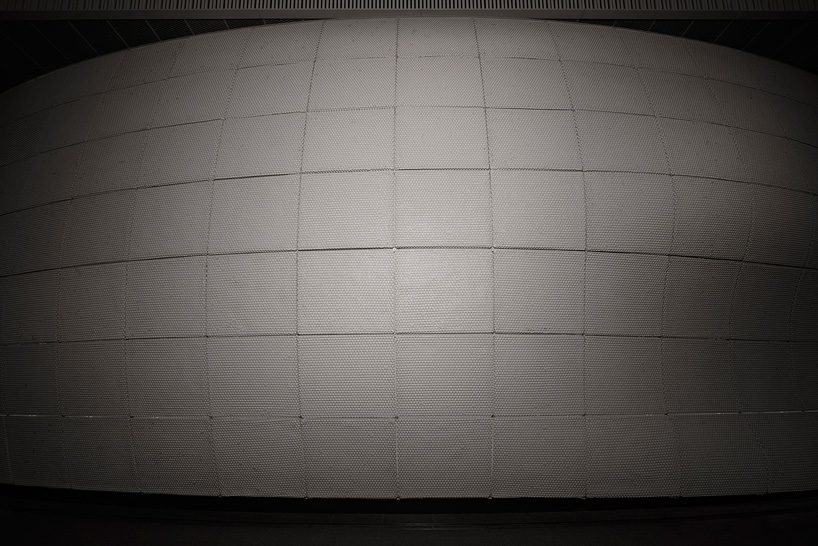

There are only a select few companies, and the process is somewhat low-tech and slow. Translucent concrete is not currently widely produced. However, as engineers continue to experiment, the cost of production will decrease, along with with an increase in demand and more widespread usage. This is due to the rarity of the product and its experimental nature. It could be about five times as much to build using translucent concrete as opposed to the traditional type. It is possible to create load-bearing structures out of translucent concrete however it would also be very expensive. Engineers can also use chemical additives to significantly increase the strength of translucent concrete. Fiber reinforcing can make translucent concrete even stronger than traditionally reinforced concrete. His tests show that “glass fibers do not have a negative effect on the well-known high compressive strength value of concrete”. Losoncze’s optical fiber concrete blocks claim a higher compressive strength of 7252 psi and a surprising tensile strength of 1015 psi even without steel reinforcing. Traditional unreinforced concrete has a compressive strength of 1000-4000 psi, and a tensile strength of 0 psi it is reinforced to gain tensile strength. New construction products must be extensively tested for strength. In Wittig’s case “lab tests showed that his panels were too fragile to withstand wind and rain”. Some experimental translucent concrete mixes have failed to produce structural consistency. The same is true of translucent concrete. How Translucent Concrete Is MadeĬoncrete mixtures must be just right in order to maintain structural strength. By switching ingredients and adding new ones, engineers have been able to create a multitude of interesting new products, one of which is translucent concrete. Other ingredients, known as admixtures, can be added to alter the concrete’s drying time, workability, color, and consistency. Bigger aggregates lead to rougher concrete and vice versa. By simply adjusting the ratio of ingredients, engineers can change the strength and texture of the material. The simple formula for concrete, however, lends itself to endless modifications. Modern concrete is most often reinforced with steel, a practice that was developed in the 1850s. Three ingredients make up the dry mix: coarse aggregate, consisting of larger pieces of material like stones or gravel fine aggregate, made up of smaller particles such as sand and cement, a very fine powder material that binds the mix together when water is added. What Makes Concrete ConcreteĬoncrete has been used since Roman times, but its basic components have remained the same. In the future, as translucent concrete becomes easier to manufacture and more available, engineers and architects will be able to utilize this amazing material in everything from furniture to entire buildings.įigure 1: Translucent concrete can be used in the exterior of buildings. They are addressing the challenges and problems that occur in every new material, and some companies have started production. Now engineers are expanding those possibilities by modifying the basic ingredients of concrete to create translucent concrete. Concrete has been called an “indispensable medium,” the “quintessential material” for architects and engineers, due to the vast “sculptural and expressive possibilities” that it can achieve. But what if concrete could be translucent, transmitting light into spaces, making them seem light and airy? Engineers today are challenging concrete to shed its opaque reputation to become both window and wall, simultaneously glowing, ethereal, and structural (see Fig.

When you think of concrete, most likely, your mind conjures up images of something solid, heavy, and monolithic.

0 kommentar(er)

0 kommentar(er)